Within process industries, stable power system operation is vital for safety and cost-efficiency. System upgrades typically focus on harsh environment resistance and future expansion capability. Underground cable pits and trenches – critical power transmission junctions – must endure water leakage, flooding, corrosion, and other environmental stresses while meeting strict standards and allowing for future upgrades. These unique requirements make process industry retrofit a highly challenging engineering task.

Roxtec uses its knowledge to tackle these challenges with a smart sealing system and full lifecycle service. For the BASF 110kV cable pit retrofit, Roxtec provided an innovative solution that transformed the underground power system from a risk-prone spot to a safety hub. The solution ensures long-term security through maintenance-free design and built-in spare capacity for future expansion.

Insight into customer needs

In the BASF 110kV cable pit retrofit project, the outdoor cable pits are 5-6 meters deep, and the pipe holes on the walls use protective pipes with an inner diameter of 175mm. The key challenge was water ingress into the cable pits. Notably, the regional rainfall has been increasing year by year, with short-term flooding during the rainy season. This, combined with groundwater pressure, caused frequent failures of traditional sealing materials, leading to continuous water ingress into the cable pits.

BASF required a solution that allows for future expansions without structural damage, demanding a sealing system with flexible spare capacity. Persistent humidity in cable pits, caused by long-term rainfall and flooding, has posed potential safety risks to power equipment. The customer urgently needed an innovative sealing solution integrating safety protection, easy installation, and easy maintenance.

The Roxtec solution

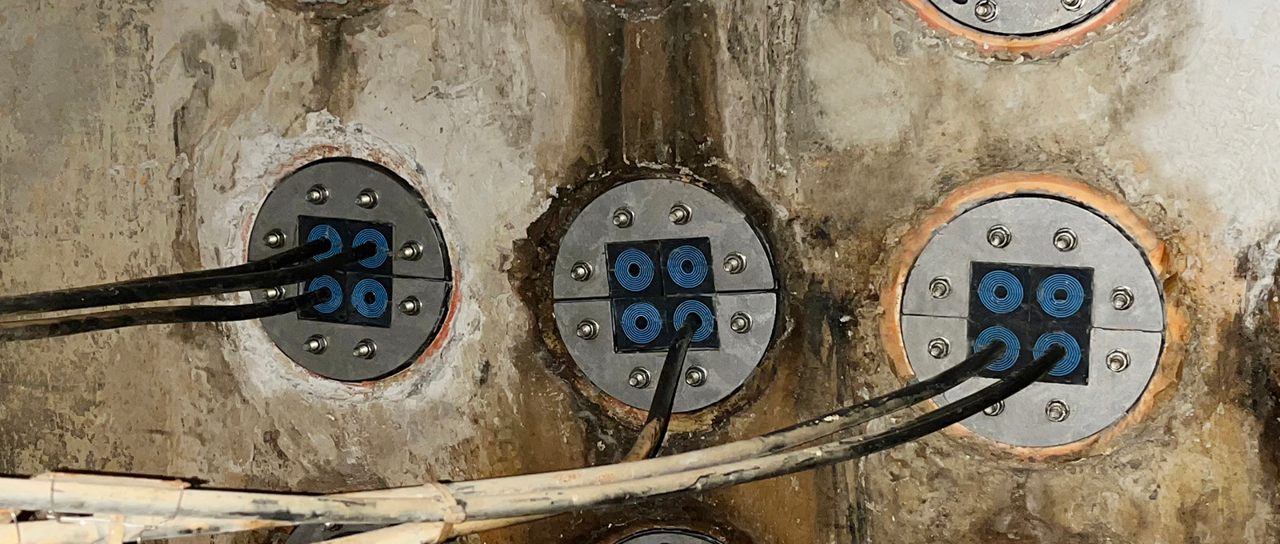

Through on-site inspections, Roxtec implemented Roxtec UG™ (underground) seals to address the complex needs of this 110kV underground cable pit retrofit. The solution effectively prevents water leakage, flooding, moisture, and rodents, establishing a robust waterproof barrier.

The Roxtec innovation Multidiameter™, based on sealing modules with removable layers, makes it easy to adapt the seals to cables and pipes of different sizes. Even if cables shift or expand during operation, it maintains sealing performance. The built-in spare capacity simplifies retrofits and upgrades, eliminating the need for wall destruction required by traditional sealing methods.

Project implementation

Using the Roxtec Transit Designer™ software, Roxtec streamlined planning and installation, minimizing design and construction timelines while preserving pit wall integrity.

Facing complex conditions, Roxtec leveraged the advantages of modular sealing and openable structures. Without interrupting power operation, it quickly completed adaptation for different cable and pipe specifications. Even in wet conditions and in environments with running water, Roxtec UG™ seals ensured efficient installation, significantly minimizing downtime.

After installation, Roxtec engineers verified the sealing performance through a waterproof and moisture-proof test, ensuring long-term stable system operation. From design and construction to future maintenance, Roxtec is committed to providing full lifecycle service.

Customer satisfaction

After completion, BASF on-site staff stated:

“During past rainy seasons, flooding in cable pits caused frequent equipment failures and production disruptions, while retrofits required wall destruction. The underground space is narrow and the operation is difficult for installers. But now with the Roxtec sealing system, water ingress has been completely eliminated. The Roxtec professionalism and commitment made the entire process efficient and ensured peace of mind."

With the Roxtec sealing system, water ingress has been completely eliminated.

Why choose Roxtec?

- Long-term waterproof

- Proven retrofit experience

- On-site technical support

- ”Future included” feature

Project facts

Project description

Power system retrofit in China

Involved companies

BASF – owner

Applications

Sealing of cable and pipe entries underground

Sealing requirements

Watertight

Moisture barrier

Rodent-proof

Roxtec products

Roxtec UG™ seals