The Baltic II is an offshore wind farm created by companies in Germany and Denmark. Roxtec cable and pipe seals protect the electrical equipment from water and humidity which is crucial for ensuring operational reliability.

Roxtec in Germany and Denmark cooperated with the parties involved to be able to deliver both standard and tailor-made sealing products for the two different types of foundations. The collaboration was a key factor in finishing the project in a quick and easy way. Another pillar of success was the frequent follow-up.

Tailor-made seals

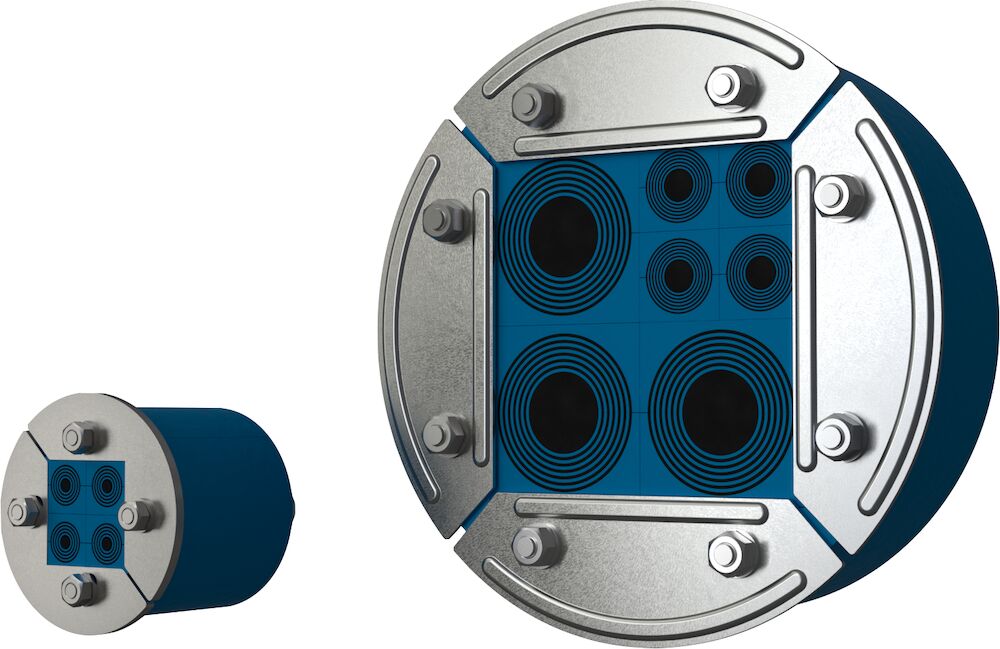

The wind turbines have a jacket foundation in waters deeper than 35m and a monopile foundation in depths up to 35m. For the cables in the jackets, Roxtec created special H seals with stainless steel quality 1.4462 and a tailor-made Roxtec H3-223 seal for the cables from the platform to the equipment in the room below.

Tight around the pipes

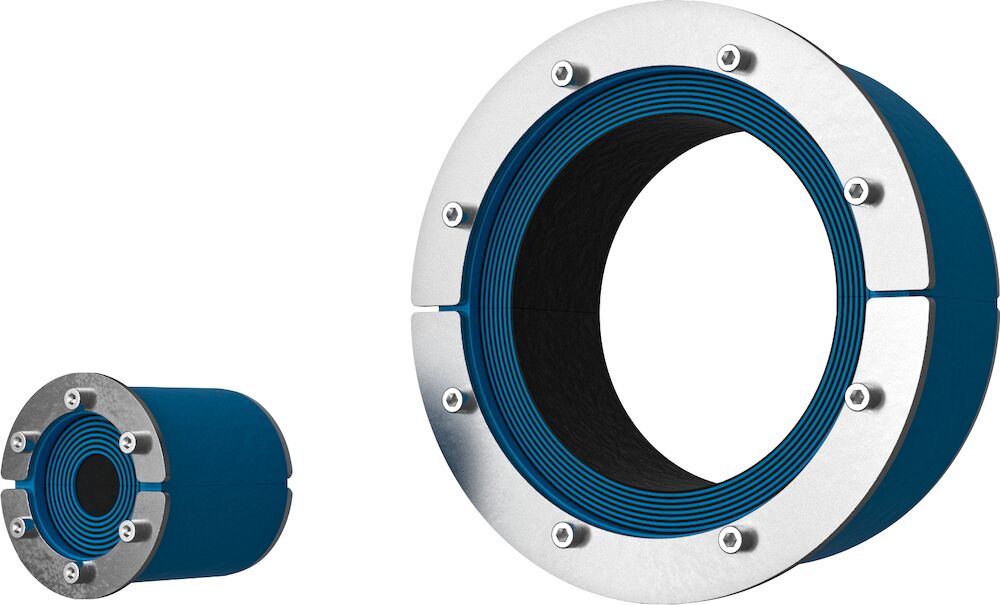

In the transition piece, the electrical cables are routed through a steel pipe below the platform. The pipe is sealed with a Roxtec RS seal and the cables on the outside are sealed with a Roxtec R multi-cable transit with special steel fittings. The pipe for the ventilation system, which goes through the air-tight deck, is sealed with a Roxtec RS seal. It keeps water and humidity out and protects the sensitive electrical equipment inside the transition piece.

Project facts

Project description

Construction of offshore wind farm

Involved companies

Ramböll, EEW Special Pipe Constructions, Bladt Industries, SAM Electronics and L3 Communications

Applications

Cable and pipe seals in jackets and monopile foundations

Sealing requirements

Water-tightness

Roxtec products

These sealing solutions were used in the project: