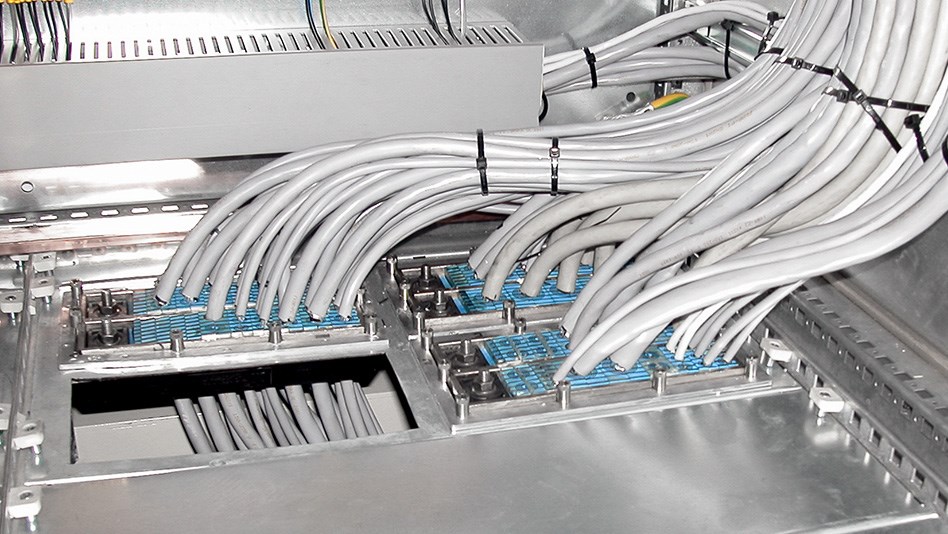

Field-based I/O cabinets call for area efficient solutions for high cable density. Up to 120 cables can enter one cabinet, and they all need reliable sealing in line with requirements.

Process automation cabinets used in oil, gas and chemical projects often require more cables than any other cabinets. If you do not want to run out of space and drill holes for cable glands in the field, you can overcome this challenge through faster, easier ways to run cables into a cabinet. It is, for example, better to use certified cable transits providing extensive capacity.

Less opening, more space

The sealing method must comply with the cabinet’s official integrity rating. You cannot use conduits because of the large amount of cables, and you cannot use cable glands because you do not want to make 120 holes and compromise the safety of the cabinet. So, what can you do? Use a unique sealing solution allowing you to run 120 cables through four cut-outs.