It is very common that mega-sized oil, gas or chemical plants lose significant production time as a consequence of failing components. That is why you should work with suppliers recognizing the importance of keeping up the performance level year after year. For example, always choose sealing solutions for cables and pipes with these requirements in mind: reduce risk, ensure operational reliability and simplify future upgrades.

It is possible to achieve safety, cost-savings and long-term productivity through a thorough selection and standardization of industry leading sealing solutions. Always think in terms of multiple demands. Make sure all cable and pipe penetration seals provide certified protection against at least fire, gas, water and the risk of explosion, and also that they form a strong barrier against rats and other animals. This is an easy way of preventing frequent risk factors from threatening business operations. Unplanned production stops are very costly and can be avoided by making quality decisions when selecting experienced solution providers.

Prepared for expansion

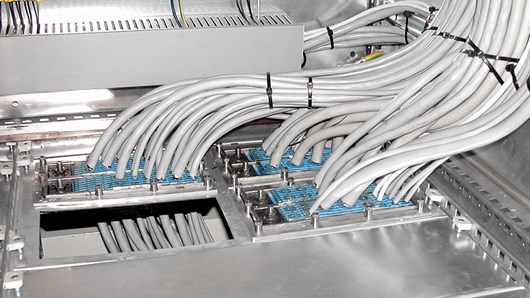

Furthermore, it is important that the seals are flexible and ready for any maintenance, upgrades and expansion – preferably without any need for drilling, hot work or downtime. The traditional way of sealing around cables and pipes with various compounds is outdated, because if you need to add a cable or a pipe you are obliged to drill a new hole and seal it all over again. Even cable glands are increasingly being replaced by more flexible solutions. The reason is that each cable gland only accommodates one cable, and punching holes for all those cable glands is both time-consuming and space requiring.

Responsible safety experts

Another thing to consider is the global aspect. International mega-projects require suppliers of solutions, products and components with a certain geographical coverage. You should only sign contracts with providers who can assist you as experienced global partners and work as integrated collaborators throughout the entire process – including tasks such as design support, onsite installation training and efficient logistics. This kind of suppliers truly reduce project complexity. Finally, a supplier of sealing solutions for cables and pipes must be a player that is clearly putting safety as high on the agenda as you are.

Are you ready to meet a global sealing expert company and evaluate a possible partnership? Do you want to gain knowledge on how to achieve safety, cost-efficiency and operational reliability?