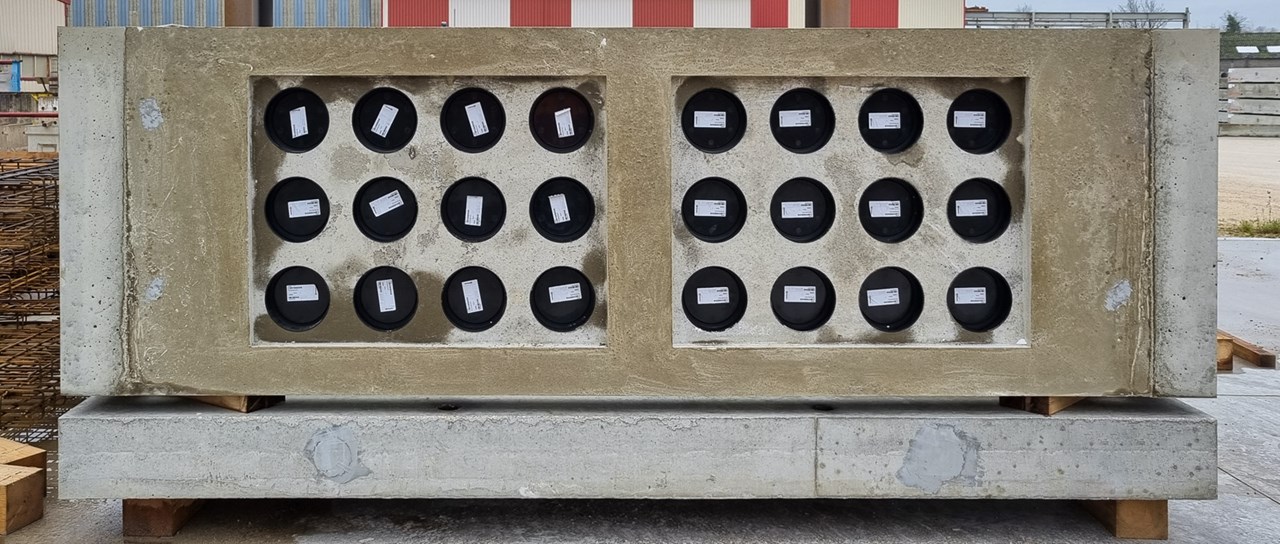

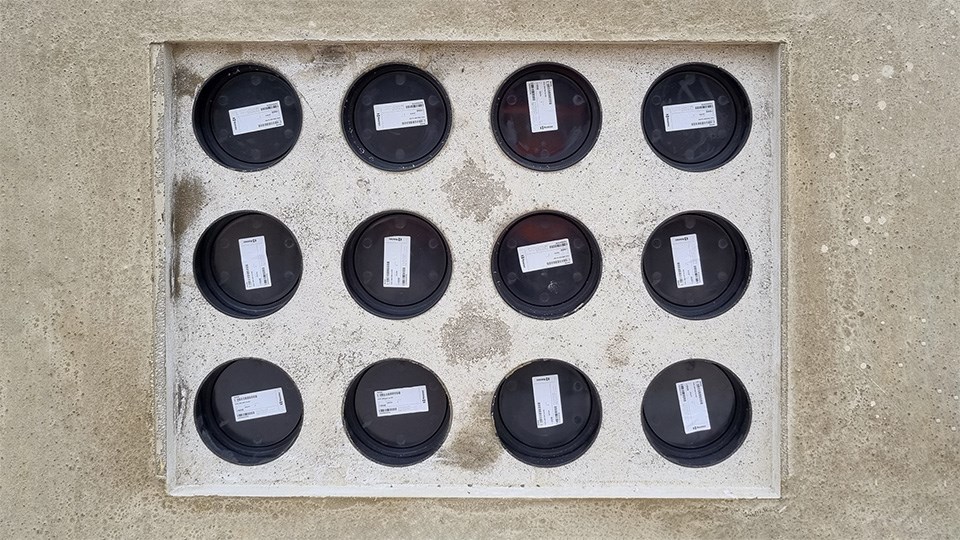

Precast concrete manufacturer Stradal in France integrates Roxtec knock-out sleeves in their manholes already at the factory. The structure is pre-sealed for the construction phase, and it is easy for the installers onsite when it is time to route and seal around cables, pipes and conduits.

“Our teams were particularly motivated to associate their know-how with the Roxtec teams,” says Jean-Baptiste Dardonville, Market Manager Innovative Solutions and Products at Stradal. “Roxtec sealing solutions cast in Stradal precast concrete pull chambers are a great opportunity to meet data center protection challenges, such as in our last major collaboration in Lisses. Watertightness and protection against fire and rodents are all challenges facing these crucial infrastructures.”

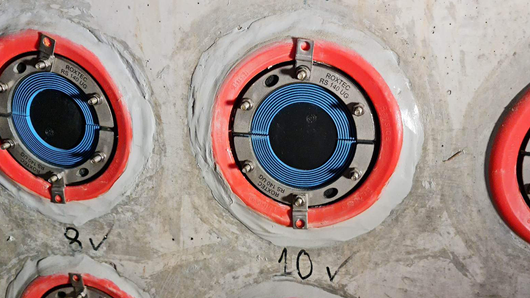

The prefabricated manholes with Roxtec knock-out sleeves are used in the data center projects Colt and Colt 2, but they can be installed in a wide variety of other buildings. Stradal recommends this complete pre-sealing solution to their end-customers for several reasons. The knock-out sleeve maintains watertightness and rodent protection while waiting for cable, pipe and conduit routing.

No need for drilling

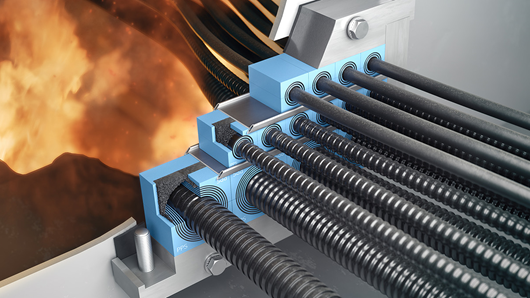

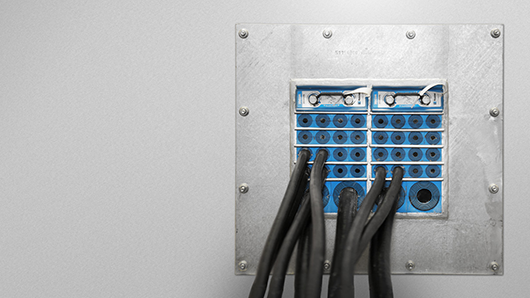

It also makes it easy for installers to manage cables and pipes in the underground transits. As the sleeve is ready for use, they can save a lot of time during installation. They do not need to drill a hole, which is often a costly and risky process as there is always a challenge in precision to avoid leakage. Now they just knock out the plates of the sleeves and insert adaptable Roxtec UG™ seals in the sleeves to tighten around all cables, pipes or conduits and thereby safely close the transits.

Competitive solution

Standardizing with large installations of Roxtec knock-out sleeves 100, 150 and 200 in the production process and letting the installer define which Roxtec UG™ solution to install is a way for Stradal to upgrade their offer, stand out in the competition and secure market shares. Additional openings with pre-sealing sleeves can also provide spare capacity for upgrades with more cables or pipes.

“There is no doubt that these solutions will soon be adapted to other sectors of activity, such as nuclear power plants, airports and sanitation,” says Jean-Baptiste Dardonville. “Our teams will be keen to continue this successful partnership with Roxtec, a professional whose high level of customized service will allow us to adapt to the technical constraints of all our customers.”

Roxtec’s customized service will allow us to adapt to the technical constraints of all our customers.

Why use Roxtec?

- Pre-sealing

- Watertight

- Rodent barrier

- Ready to use

- Simplifies sealing

Download the pdf-version of the Stradal, France case.

Project facts

Project description

Prefabrication of pre-sealed manholes

Companies involved

Stradal – owner, design and engineering

Applications

Pre-sealing of cable, pipe and conduit entries in prefabricated manholes

Sealing requirements

Watertight, Rodent protection

Roxtec products

Roxtec knock-out sleeves and Roxtec UG™ seals