Here are 5 reasons for choosing Roxtec Multidiameter™ for your multi-cable transits (MCTs). Besides ensuring protection against fire, gas and water, you benefit from increased efficiency: cost savings, smooth logistics and ability for expansion. Also, the adaptable modules increase your chance to handle non-planned, but not uncommon, changes on site.

1. Quality is more cost-efficient than quantity

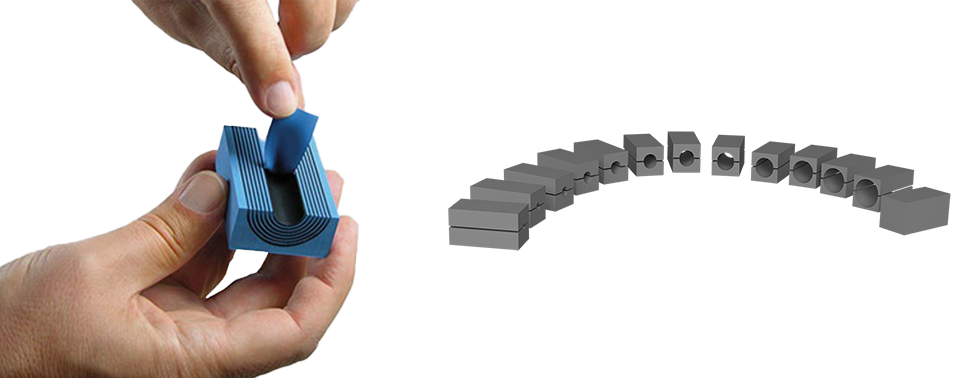

If you use a Roxtec sealing module, you can adapt it to cables of many different sizes. You just peel off rubber layers until it fits perfectly around the cable.

If you use a fixed diameter module, you may need many more with varying sizes of cable accommodation space to find one that fits. It must fit; protection cannot be certified with a module of the wrong size.

You would, for example, possibly need up to 14 modules with fixed diameters and a solid block module to cover the spectrum of possibilities provided by a Roxtec RM 30 module with Multidiameter™.

2. Flexibility enables truly simplified logistics

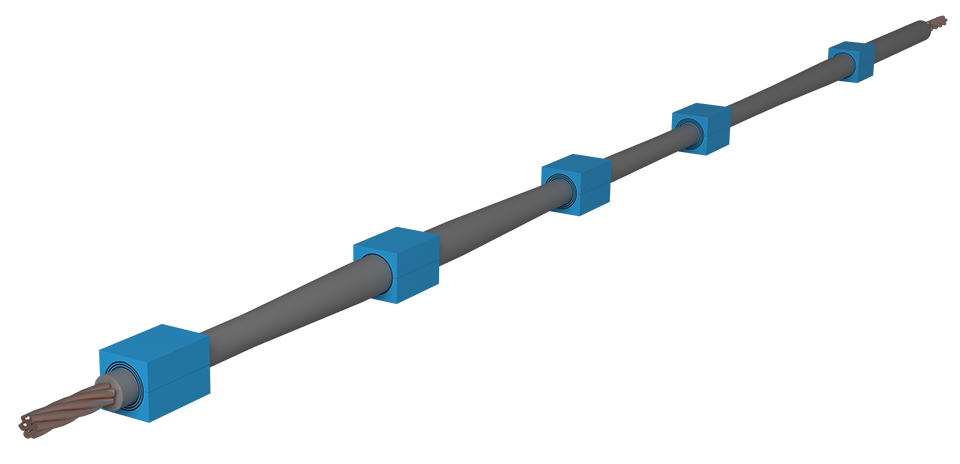

Using Roxtec modules, you only need six sizes to cover cables with outer diameters from 4 to 99mm. You manage the work with fewer items on site and a minimal stock.

To cover that diameter range, you may need up to 60 different sizes of fixed modules. Even if the fixed modules have a tolerance of 1-3mm, they get harder to pack and seal. You will have to keep many modules in stock – and often bring too many of them back and forth. Every line item you add into your enterprise resource planning system may add extra work and cost.

3. “Future included” turns space capacity into spare capacity

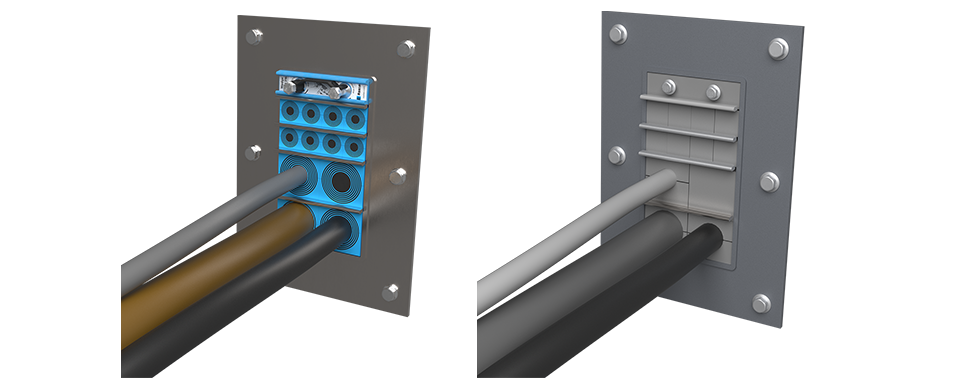

If you use a Roxtec module, you can use it either for sealing a cable or pipe entry or for ensuring built-in spare capacity for a future cable – which can be of a size you do not yet know.

With a solid filler module, you only have extra space – not real spare capacity. If you want to add a cable, you need to open the transit, remove the solid module block that is filling up the space, and then replace it with a new sealing module – which must be in the exact right size for the cable. This means, again, that you may need a lot of modules.

So, with Roxtec, you can add new cables without any need for adding modules. If you use fixed ones, however, you must add a new module for every cable you add. Note: some fixed systems require that you replace all modules if you have opened the transit.

4. The stated nominal cable outer diameter differs from the real one

One size fits all. With only one size of a Roxtec module with Multidiameter™, you can handle a wide variety of cable manufacturing tolerances thanks to the peelable rubber layers.

A simple analysis of technical data for four 11kV 300mm2 aluminum cables from four different cable manufacturers (see table below) shows that the same type and category of cable – a cable type that meets the exact same international standards and requirements but is produced by different manufacturers – can differ significantly in overall diameter. With this variation, it is hard to ensure the actual cable size in the purchasing phase as all four cable brands can be approved for use. This can cause issues from design and purchasing through to installation – and huge extra costs.

Fortunately, you can adapt a Roxtec module to the actual cable dimension right where you are, and right on site. It does not matter that the cable outer diameter (OD) varies a lot from the stated nominal OD due to generous tolerances in cable manufacturing. No matter where the cables come from, you can efficiently handle the sealing challenge. If you need to replace an existing cable or route a new one to upgrade, you do not really need any detailed knowledge about the cable manufacturer or the cable outer diameter.

|

11kV 300sqmm alu cable |

||||

| Cable manufacturer | Nominal outer diameter | Typical production tolerance | Roxtec module | Fixed outer diameter |

| A | 35.6 | 33.6-37.6 | RM60 | More than 7 different sizes |

| B | 36.4 | 34.4-38.4 | RM60 | |

| C | 38.1 | 36.1-40.1 | RM60 | |

| D | 46.6 | 44.6-48.6 | RM60 |

If you use a fixed module, you may need many more of various sizes for the same cable type. In this case, you would probably need to check each cable outer diameter and bring more than seven fixed module sizes to cover the variations. The cable tolerances range from 33.6 to 48.6mm overall diameter. This range is covered by one Roxtec RM60 module with a tolerance of 28-54mm, but would need more than seven variations with some fixed systems.

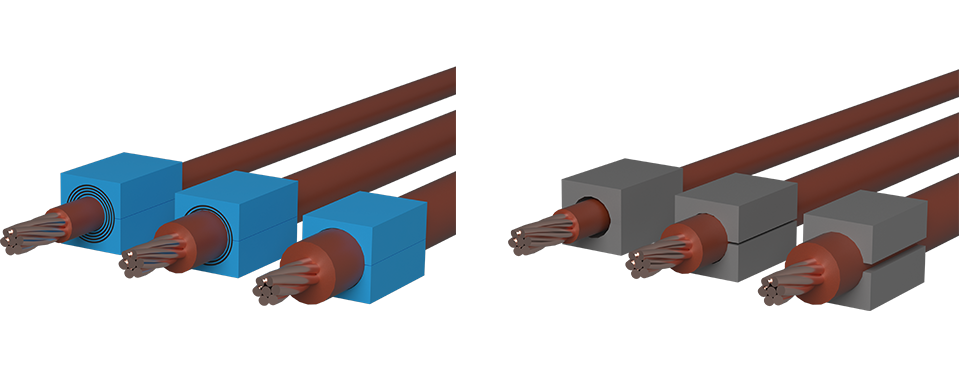

5. Cable dimensions are never even along the entire cable

Also, a specific cable from a specific cable manufacturer can vary a lot in overall diameter. Although there are variations in the production, it can still be within the manufacturing tolerance. Imagine a 500-meter cable that is to pass through five transits, and the cable has potential to vary in overall diameter along the length of the cable run.

Roxtec modules provide enough flexibility for you to manage the task of sealing the five penetrations along the cable with only five modules of the same size.

A fixed module, on the other hand, may not have the tolerance needed. You may need to order, stock, and bring a whole bunch of modules to cover the varying cable diameter.

It is certainly easier to adapt a few modules than having to carry loads of them to site.

To summarize, there are some common cable sealing challenges that can be hard to overcome with fixed diameter modules. If you do not know the cable brand or the cable manufacturing tolerances, or if there is a change or need for additional cables and seals, you risk buying, transporting and even wasting too many modules. With flexible sealing modules from Roxtec, you can just carry on performing your work in a safe and cost-efficient manner.

Learn more about Roxtec Multidiameter™ here.

Evaluate the differences according to your project context

Flexibility can offer clear benefits where variability is expected, while fixed sizing may be preferable when cable or pipe dimensions can be guaranteed. It is important to remember that neither approach is inherently better in meeting performance requirements; the key lies in matching the usage of solution to the certainty, constraints, and priorities of the project.