Design and engineering companies all over the world appreciate the free, online tool Roxtec Transit Designer™ and use it to simplify design of cable and pipe transits. OMT, Odense Maritime Technology, in Denmark is one of them.

Chief Process Officer Niels Ammundsen at OMT explains how very important the web-based application is in their navy ship design projects:

"We save a lot of time, up to 80 percent, especially when changes are needed."

Niels Ammundsen

According to Niels Ammundsen and his colleagues Claus Ebbesen, head of electrical/automation department, Tommy Nørmark Christensen, electrical designer, and Kent Bøtchiær Dam Olsen, S3D support group at OMT, the major benefit in a recent project was that the tool helped them track and follow the filling rate of each cable penetration.

"We had 1,000 penetrations and strict margins. The customer required 20 percent capacity for future installations and detailed control of the spare margin along the project. We used Roxtec Transit Designer to make sure we had enough space."

Real time updates

The team was able to monitor the development and provide real time updates on a day-to-day basis regarding the cable transit filling rate. This reassured the customer who wanted to avoid the risk of having to cut new or modify openings.

"The tool helps us monitor how we use the space in the ship and to respect the margins. We can also see if there is capacity available in other cable transits."

80 percent time-savings

The OMT team estimates their time-savings with the Roxtec Transit Designer to 80 percent when compared to sizing and keeping track of the transits manually.

We save a lot of time, especially in the later stages or when changes are needed. We also reduce risk, as we identify issues before they become reality in the yard.

Sharing work online

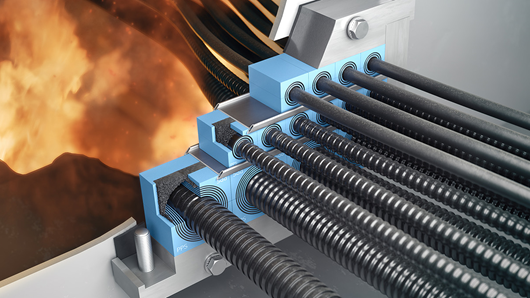

The team appreciates the user-friendly interface, the integration with design programs such as Intergraph Smart 3D, the visuals on how to pack the Roxtec sealing modules and the ability to share work with project members online.

"We have the ability to share this project and its documents online with our designers at other locations and eventually hand over the project to our client as a supporting tool during production."

The OMT team uses the tool to make sure they select a sealing solution that complies with all requirements, and to be able to size the transits correctly.

"We know from previous projects that Roxtec products will do the job and that they have all the certificates needed regarding fire protection and gas-tightness."