The Nochten open pit mine is crawling forward at a speed of two meters per day.

Giant bucket-wheel excavators remove sand and extract lignite, or brown coal, to feed the steam-electric power plant, while the overburden is sent back on an extensive conveyor belt system for rehabilitation of the landscape. Vattenfall Mining Europe has specified Roxtec seals throughout the operational chain.

All over the mining area

Vattenfall Mining Europe has very good reasons for specifying Roxtec. This German large scale open pit mining environment requires total dust tightness since the coal dust is conductive and may cause an explosion. Roxtec seals are tested, certified and known for protecting sensitive equipment from water, humidity and dust.

Roxtec seals are used in everything from communication shelters and power substations along the mining area, to conveyor belt drives and excavators working to extract coal 100 meters further down in the pit.

Ensuring protection

Operational reliability is crucial both for feeding fuel to the power plant and for land refill and rehabilitation. If an excavator, a crusher, a conveyor belt or a spreader stops, all activities will go down. Reduced output and increasing energy prices are not what Vattenfall and the German society want. It is comforting to know that even small safety components, like cable seals, are selected with care.

Why use Roxtec?

- Dust-tight

- Watertight

- One solution for many applications

- Openable seals for easy maintenance

- Built-in spare capacity for additional cables

Project facts

Project description

Open pit lignite mining in Germany

Owner, design and engineering

Vattenfall Europe Mining AG

Equipment manufacturer

BEA Spremberg

Electrical installations

Elektro Pfeiffer

Applications

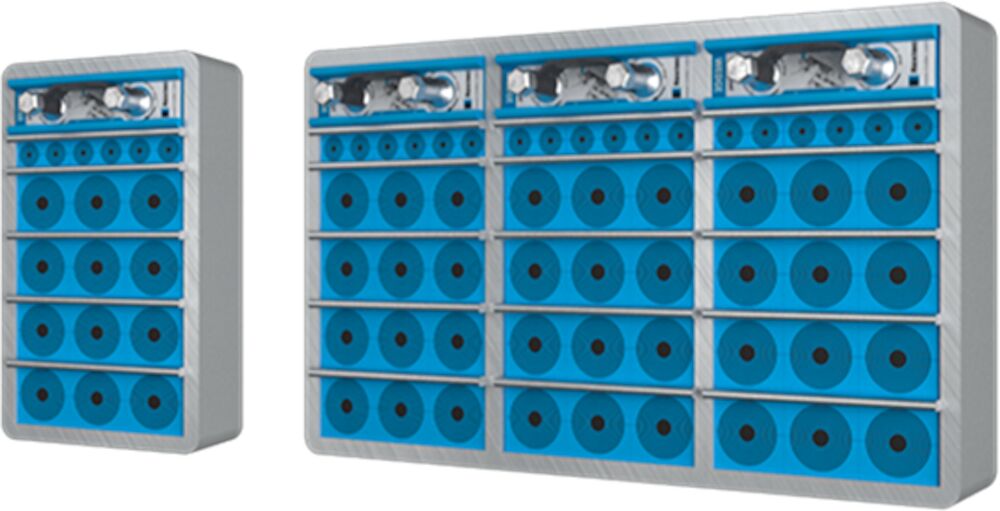

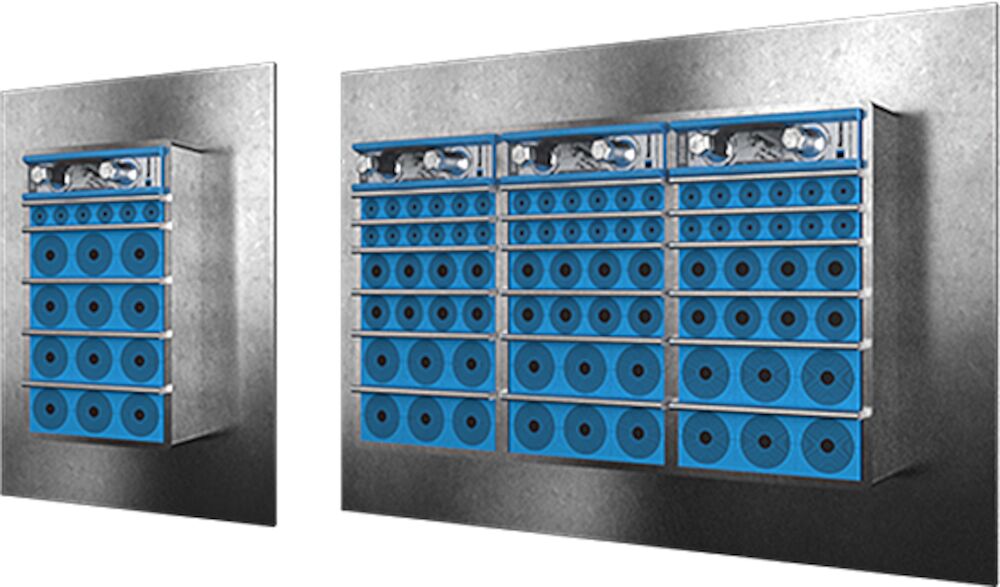

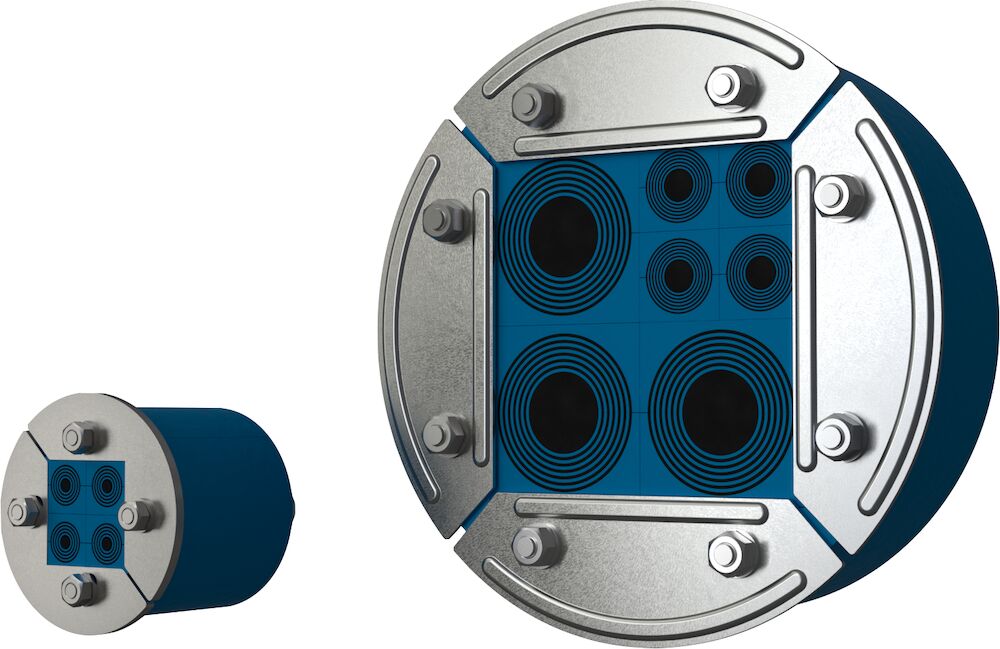

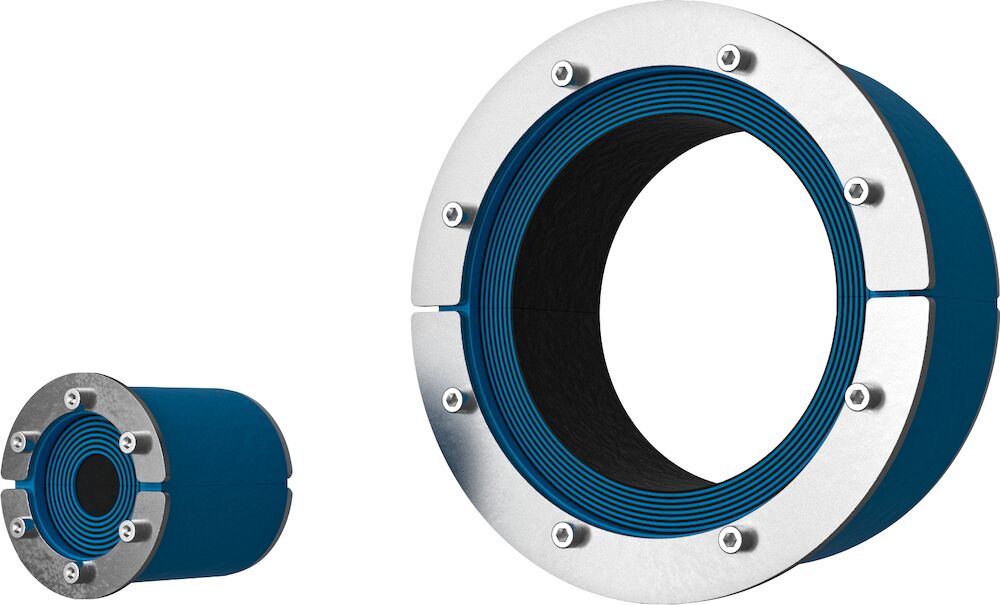

Sealing of cables and pipes in control cabinets, control shelters, converter systems, excavators, crushers, spreaders and conveyor belt systems

Sealing requirements

IP 66/67

Roxtec products

These sealing solutions were used in the project: