Rail Network Alliance wanted to protect the new South Yarra underground electrical substation from fire, water, and rodents. They selected Roxtec seals for the cable and conduit entries.

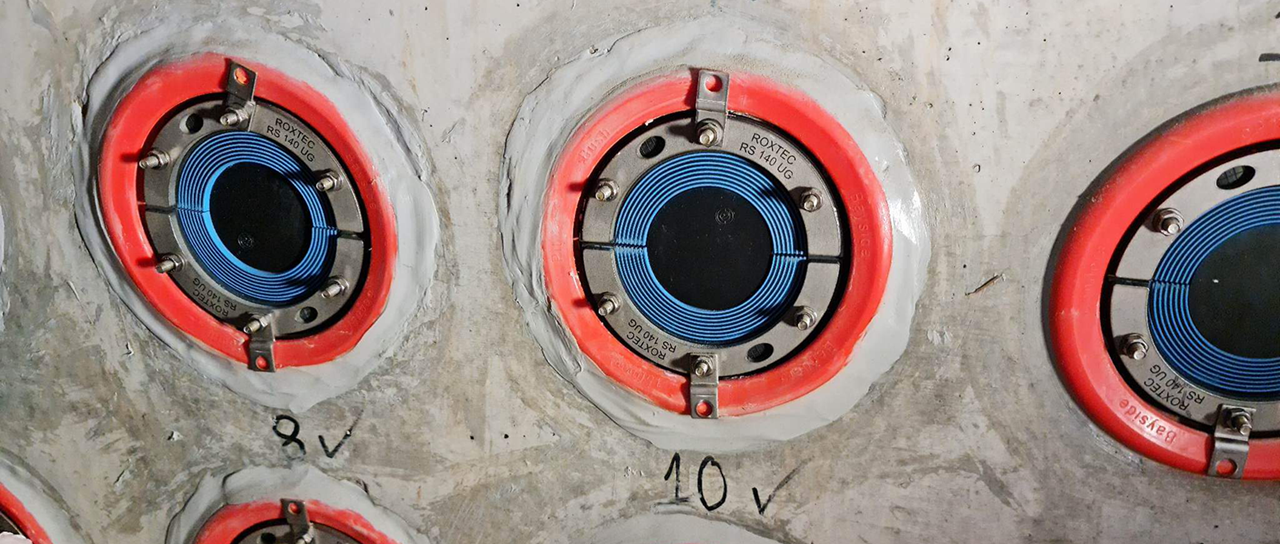

“Roxtec UG™ seals were selected to seal the underground conduit entry points against constant water pressure for this project,” says Michael Adams, Engineering Lead – Power Systems and Construction Lead – South Yarra Substation of Rail Infrastructure Alliance.

The new substation, located at the eastern portal of the Metro Tunnel, is required to increase the capacity on Melbourne’s rail network along the Sunbury, Cranbourne, and Pakenham lines. It is located underneath the South Yarra Siding Reserve, so there are stringent technical requirements to reduce its impact. The reserve has been upgraded and is being returned as open space area for community use.

The importance of sealing underground

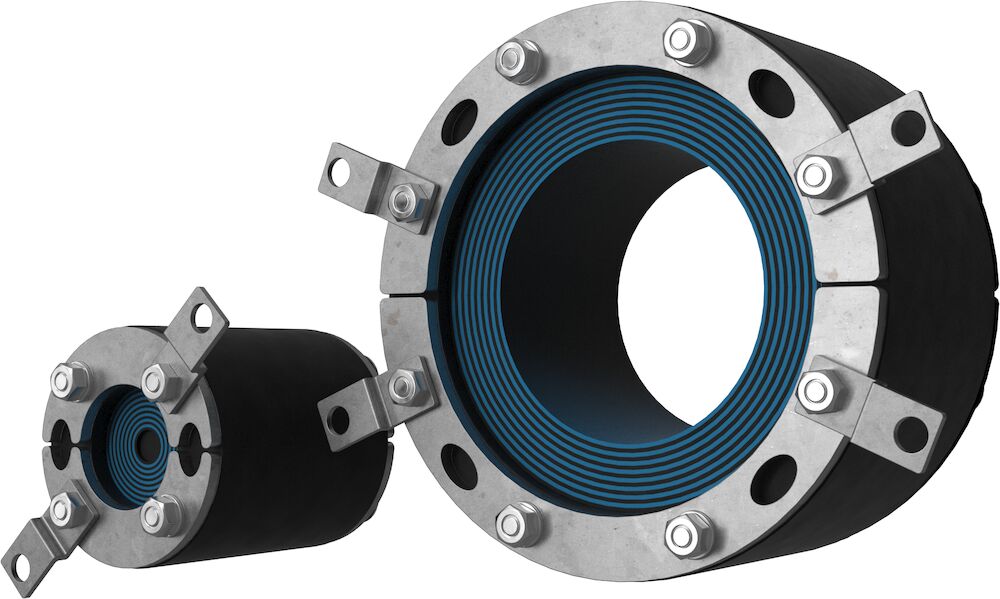

The substation is built underground, and the designers needed to consider water ingress into the building. They used a water membrane system to protect the building elements in contact with the soil. They realised they needed to find a sealing system to ensure no water entered via the conduits penetrating through the walls and floor. Roxtec UG™ seals were specified for all conduits entering the building.

These conduits were of different sizes and contained various cable diameters. There was also a requirement for future capacity. The main electrical conduit size was 150 and when there were two or three cables in the conduit, they used the Roxtec H3 142 UG™ seal, which is developed for the Australian market. It was very important to avoid the issues caused with water ingress and thereby simplify maintenance work.

Extensive wall penetrations

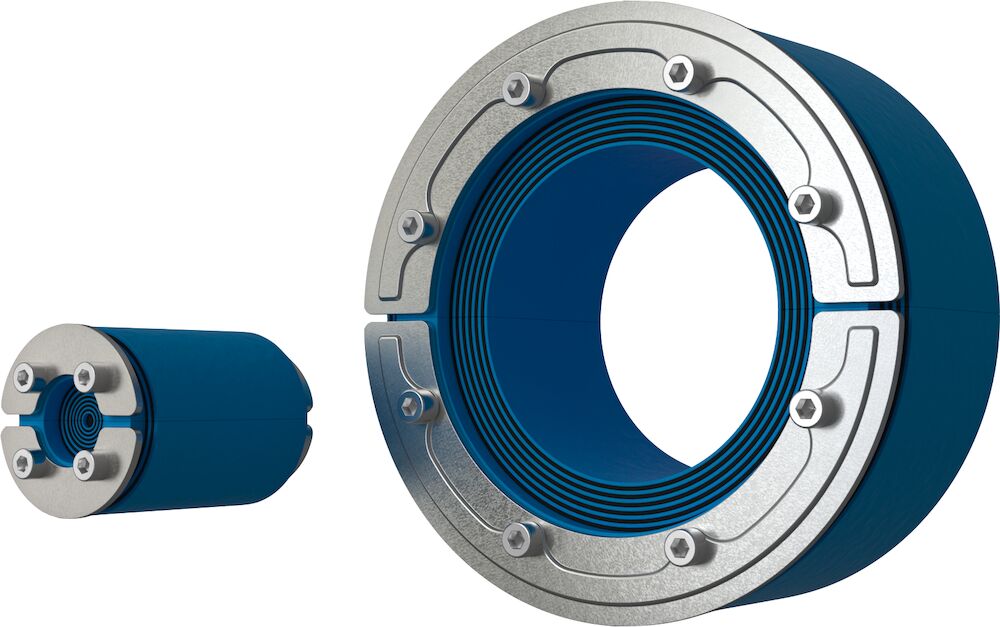

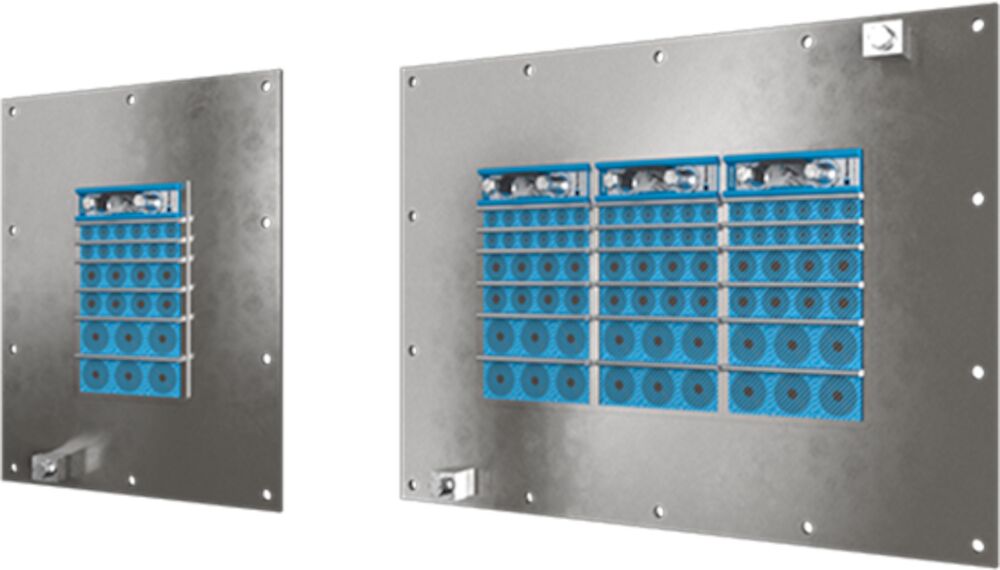

The Roxtec transit system was used to seal where the transformer/rectifier cables penetrate through the external wall. The system was required to withstand fire with an FRL-/120/120, protect against weather exposure and provide an earthing lug. The cable spacing requirements were critical to suit the equipment.

The close collaboration between the specifying Rail Network Alliance partner AECOM, the construction alliance team and Roxtec Australia ensured the apertures for the cable penetrations were correct and the transits accommodated the specific cable spacings.

Roxtec provided onsite support and guidance for the sealing installation. The collaboration between all parties ensured the whole process, from design to construction and completion, went smoothly.

“The Roxtec transits were the approved solution as they met Australian fire requirements, protected against harsh environmental factors and were able to accommodate the critical site cable penetration locations,” says Michael Adams.

The Roxtec UG™ seals were selected to seal the underground conduit entry points against constant water pressure.

Why use Roxtec?

- Certified fire protection

- Watertightness

- Rodent barrier

- Space efficiency

- Onsite support

- Built-in spare capacity

Project facts

Project description

Construction of underground electrical rail substation in Melbourne, Australia.

Involved companies

Victoria Department of Transport – owner

Rail Network Alliance (comprising of John Holland, CPB

Contractors, Alstom, AECOM, RPV and Metro Trains) – engineering, construction, and installation

Applications

Sealing of entries for cables and conduits in walls and underground.

Sealing requirements

Fire-rated

Watertight

Rodent-proof

Roxtec products

For conduits: Roxtec UG™ seals, RS 140, H3-142, R 100/6, R 100/4, and RS 50 OMD

For external wall penetrations: Roxtec GH BG™ 8x2 FL100/6 stainless steel kit with RM 60, RM 30/0 and RM 15w60/0 sealing modules